Electricity & Instrumentation

Your turnkey electricity-instrumentation package !

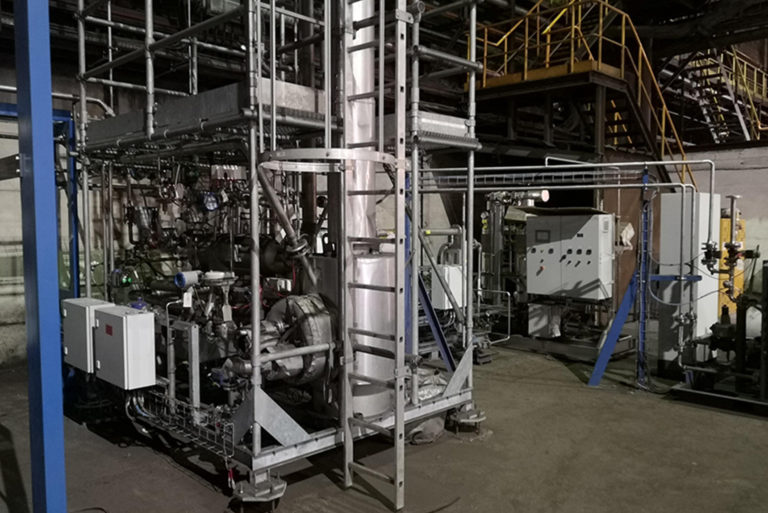

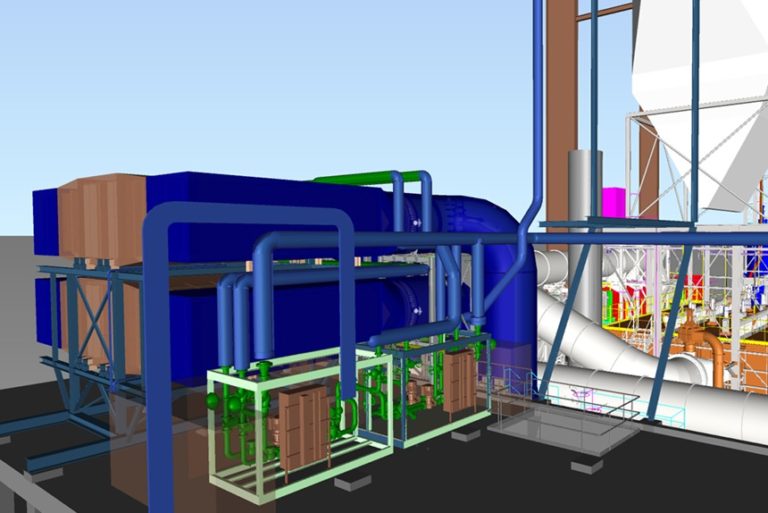

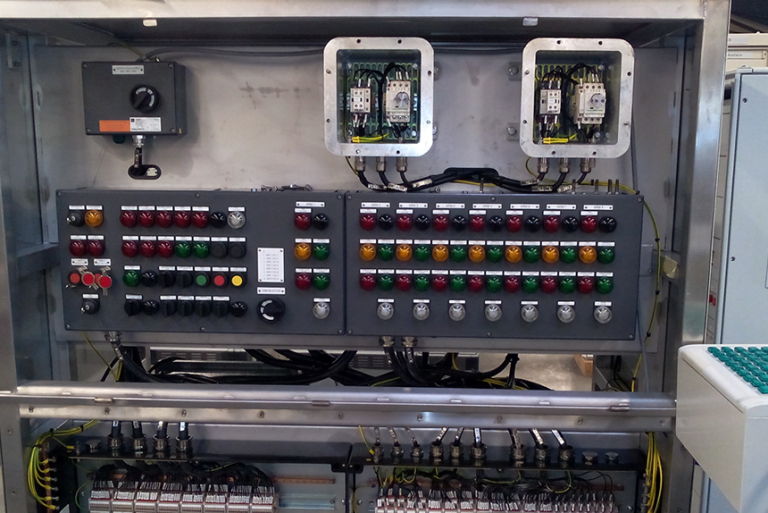

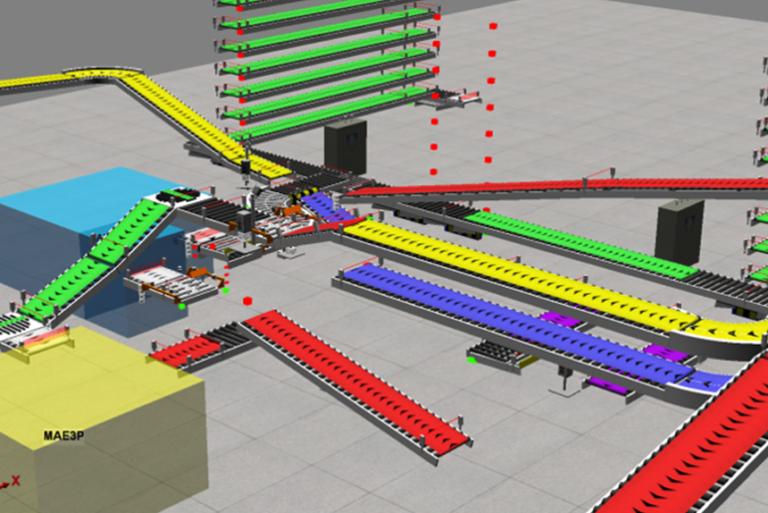

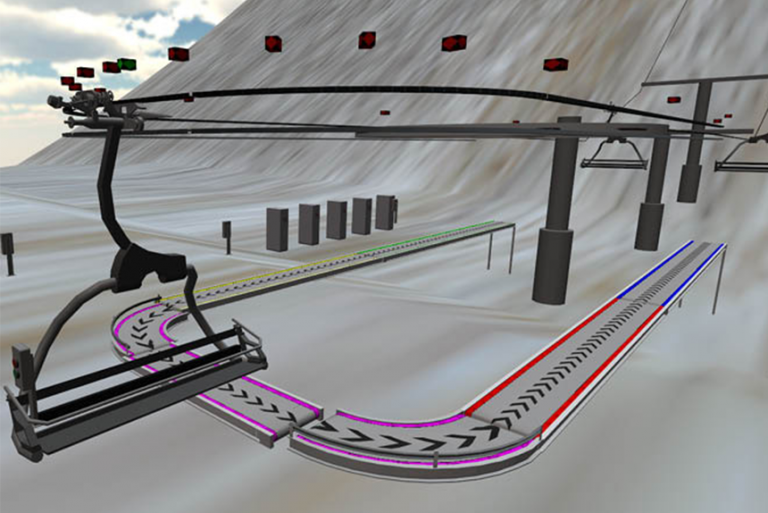

From HTa to low current, we have respected skills in industrial electricity, founded in over 20 years of experience. We conduct audits and provide on-site counseling, readings, design and schematics, plant studies, manufacture of electrical equipment, electrical works, and on-site service.

An engineering firm steeped in industrial culture and international standards, we guide our clients by offering them a contractual framework and customized work : outsourcing, co-sourcing, back-to-back via outsourcing or via business groupings.

Our transparent approach on the points identified as critical, in particular through our technical experts’ guidance about work methods adapted to different types of plant, guarantees the success of your projects.

OUR EXPERTISE

Electricity & Instrumentation

- HTA

- Transformers

- MCC Cabinets

- PLC Cabinets

- Variable speed drives

- Electrical Shelters

- Power and control cables

- UPS

- Control boxes

- cooling units

- Busbar

- Explosion-proof envelopes

- Import/export of energy

- Design Calculations

- One-line diagrams

- Wiring Diagrams

- Electric layout

- Nomenclatures

- Marine Certifications

- Standards (ISO, BS, NEC, CA, DIN)

OUR PARTNERS