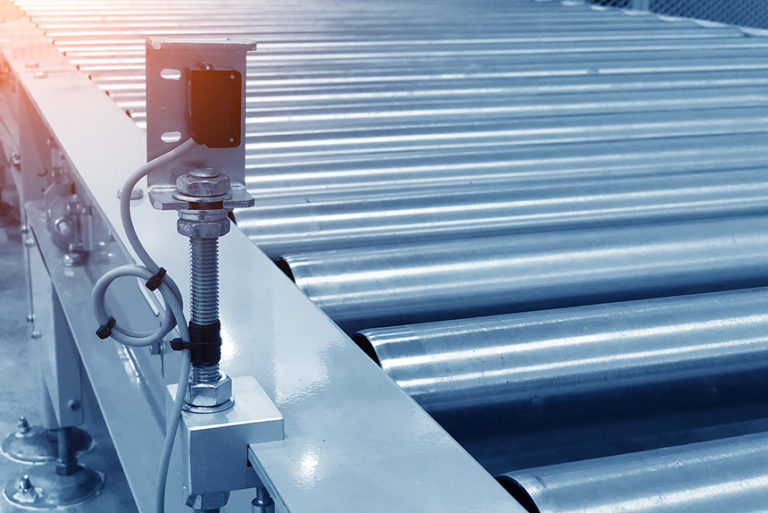

Automation

Industrial automation is in IESA’s DNA !

Within the community of automation engineers we are well-known for our high degree of software and hardware expertise.

We have at our disposal large production and integration capacities, tried and tested work methods and an internationally-mobile workforce.

Our clients entrust us not only with programming their automata, supervisory control / monitoring, and Human Machine Interfaces (HMI), but also with the realization and maintenance of their programming standards.

The high performance level of our services has led us to specialize in « high-risk » projects.

Projects presenting substantial technical challenges or high financial stakes, requiring continued heightened levels of service, like for example the optimisation of complex plant processes or the revamping of automated plants requiring a rapid changeover from old to new systems.

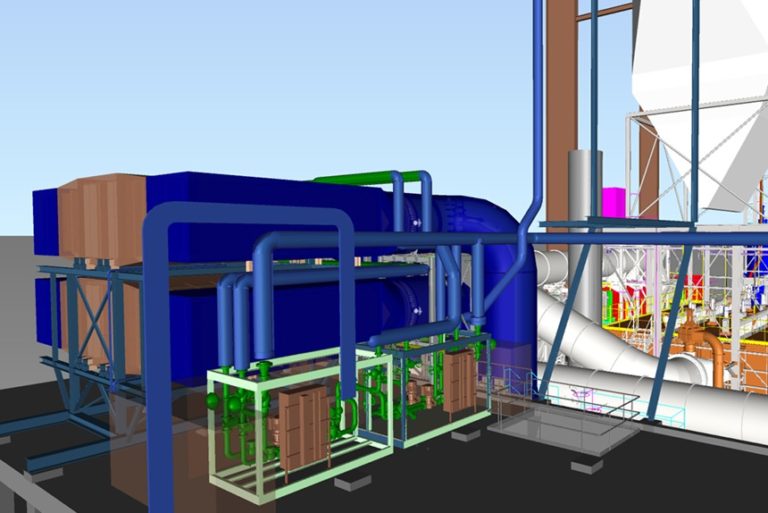

Our expertise

Automation

- Programmable logic controllers (PLC)

- HMI terminals

- Process supervision / monitoring

- International commissioning

- PLC architecture

- SIL (Safety Integrity Level)

- Operator training

- Redundancy systems

- Functional analysis

- Organic analysis

- Gemma

- Study of PID control loops

- Fieldbus network

- Quality control software

- Security analysis

- Conversion of programmable logic controllers (PLC)

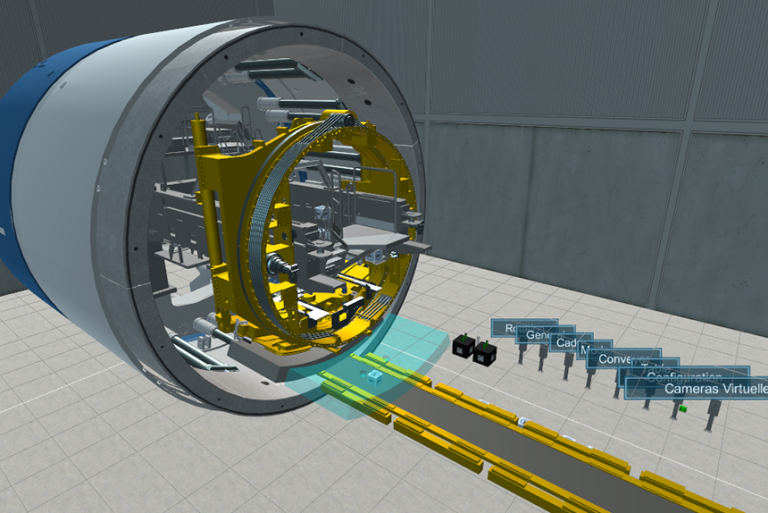

Our partners