Business News – Rewriting electrical diagrams for a pneumatic plant in Germany

Another new deal in the Logistics market!

The logistics market presents key challenges in meeting consumer expectations while complying with safety standards. It is constantly evolving, driven in particular by technological innovations to optimize warehouse management. The aim of intralogistics is to improve efficiency, precision and productivity by ensuring the smooth flow of materials and products to the various points in the warehouse.

IESA has been present in this growing and demanding market for many years, and has solid references in this field, thanks in particular to its recognized expertise in Transitique. Firmly focused on expertise and innovation, we have a solid knowledge of the sector and its various processes, as well as solutions appreciated by the sector’s major players.

As a result, we have just won a new contract in the logistics market, and more specifically in the pneumatic handling market.

Our assets for this project

We’ve been working in the industrial automation sector for almost 20 years, whether for tire curing workshops, parcel sorting centers, kitchen production warehouses, or food processing plants.

We’re involved in automation as well as instrumentation and electricity. Our industrial electricians have solid skills in audits, the design and schematic of your installations, the management of electrical work contracts, whether partial or complete, and the manufacture and supply of electrical equipment.

Our proven experience gives us a global vision, and an international industrial and standards culture appreciated and sought after by our principals.

What is the scope of the project?

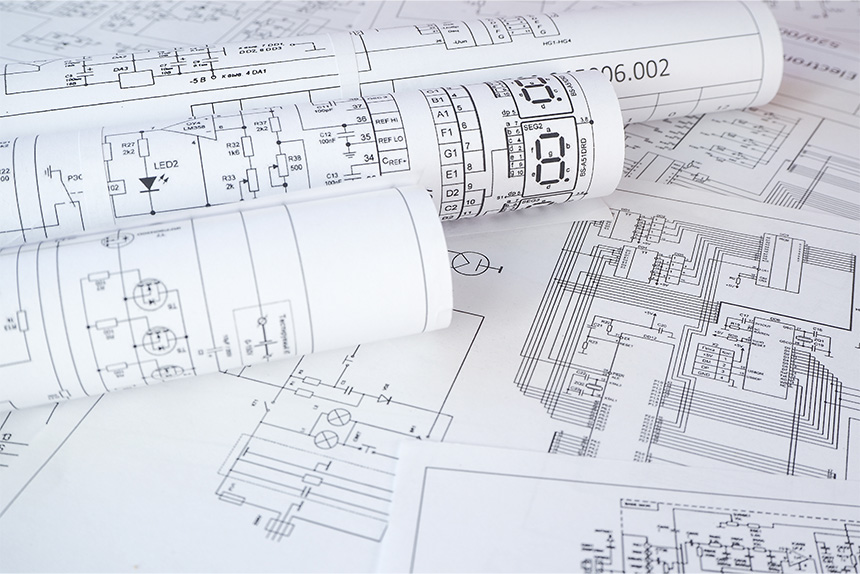

We’ll be taking part in a project to rewrite the #electrical schematics, initially developed using old software, for delivery using SEE Electrical, with the Michelin environment.

This will improve the clarity and legibility of the electrical system managing the plant’s various workshops. They will also meet our customer’s safety and quality standards, as well as environmental standards.

The rewriting of electrical diagrams is an essential step in the management and maintenance of electrical systems, as updated and highly accurate diagrams are crucial to ensure the safety, reliability and efficiency of electrical operations.

This project concerns 2 complete transitic systems for the after-curing and retreading workshops of a #Trucks tires plant.

Transitic systems are automated systems used in logistics, manufacturing and other sectors to move, sort, store and manage goods, materials or other objects efficiently and automatically. These systems are designed to improve the productivity, precision and speed of handling operations.

In a tire factory, the before-curing workshop is responsible for preparing materials and creating raw parts, while the after-curing workshop is responsible for curing components, inspecting them and preparing them for export.

We work for both types of workshop on a regular basis.

Thanks

We would like to thank our Michelin customer for his trust and loyalty. In fact, he never hesitates to consult us on different projects and different sites, depending on the particularities of each project.

Coming soon

We know that many of you are interested in finding out more about the technical details of the project. We’ll get back to you very soon with further information as our mission progresses. Feel free to stay connected by subscribing to our LinkedIn page and visiting our website regularly.

To find out more

To find out more about our skills and references in the logistics market, CLICK HERE

To consult our technological focus on the subject: CLICK HERE