Recognized expertise in the logistics market

The logistics market is constantly expanding and offers a wide range of process typologies. IESA has been involved in this market since 2005, when it won its first contract for a logistics project! Thanks to its technical expertise, whether in automation, instrumentation or process simulation, IESA is regularly called upon by customers!

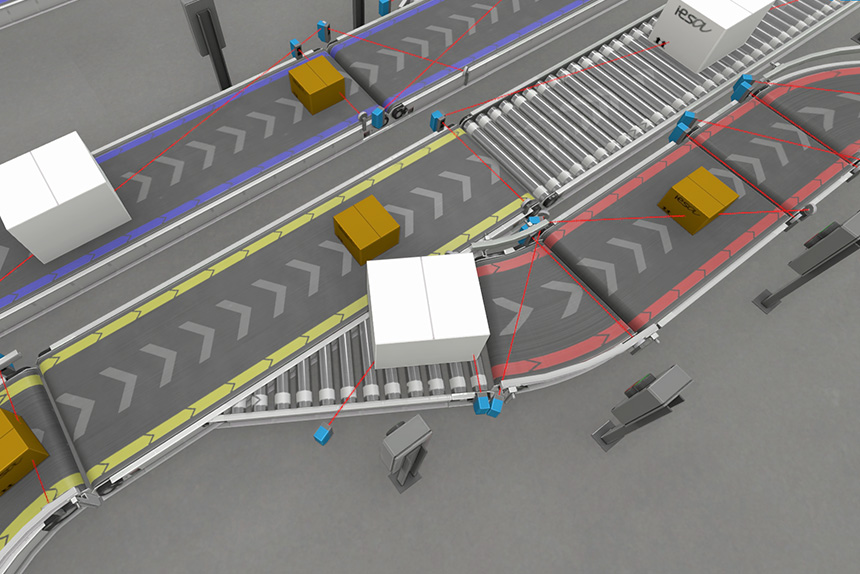

Safety is a priority in parcel sorting centers!

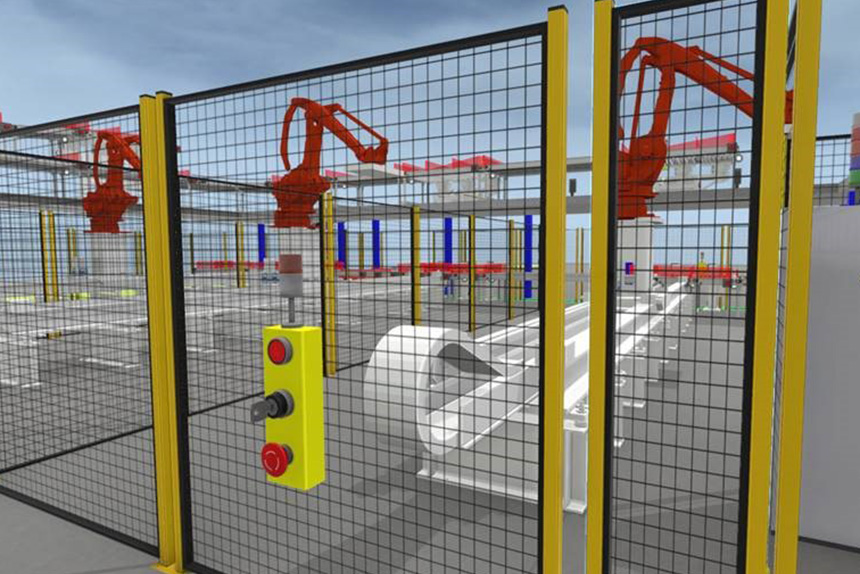

The “sorting center” process for packages of all sizes is an environment in which we regularly work! Whether it is on the control part with the management of the electrification or the automation of conveyors/sorters such as shoestorter, crossbelt sorter… Or on the functional part with the integration of level 2 or even on the management of safety devices such as emergency stop.

Concerning instrumentation, our scope generally includes studies, sizing, design and supply of cabinets, as well as installation and commissioning on site.

Our scope of work in automation is not limited to the programming of PLCs. It also includes the functional and organic analysis as well as all the tests necessary for a successful commissioning!

Safety management consists of developing, programming and implementing a set of SIL3 safety PLCs. The batches and equipment are CE certified after the intervention of our technical experts by certification organisms such as APAVE or Bureau Véritas. This approach allows operators to work in complete safety in the various production workshops.

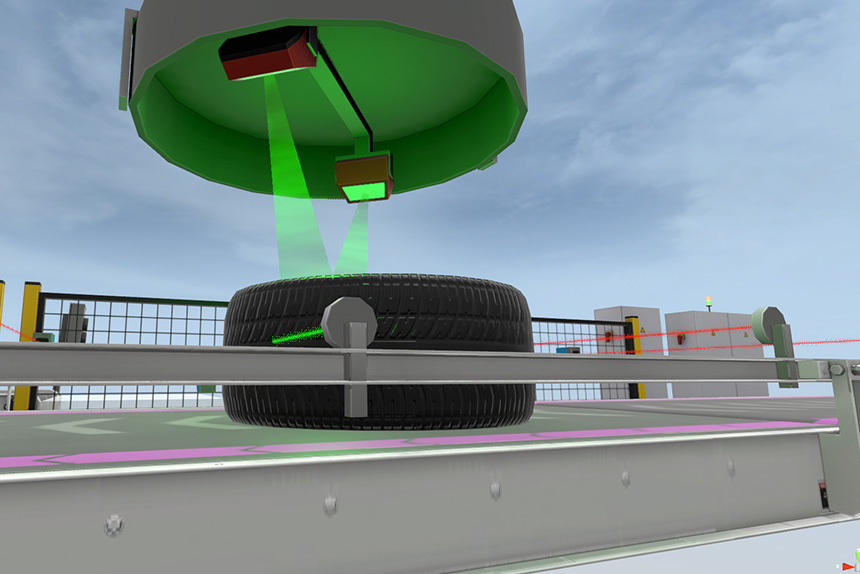

3D modelling for stacker cranes

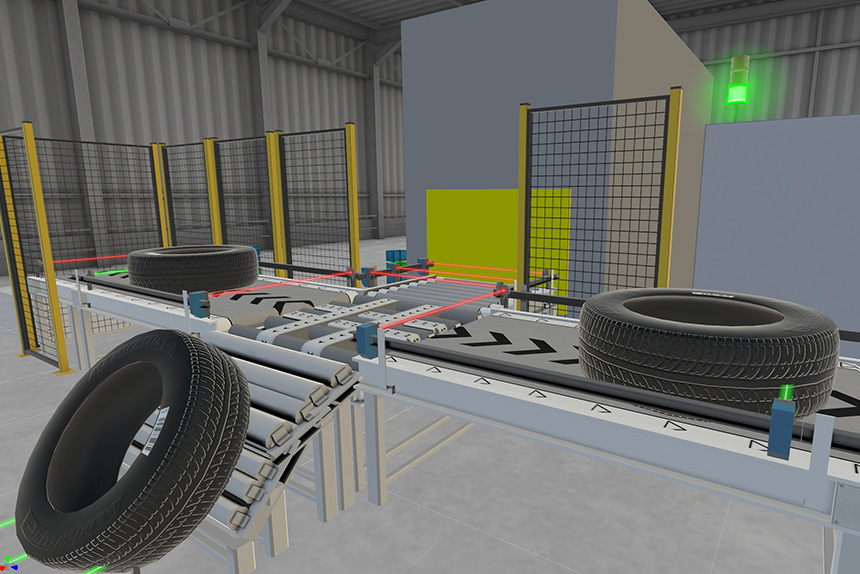

The first need on this process is to verify that PLCs are properly configurated and I/O are correctly adressed. The different tests allow us to validate :

- The installation is able to absorb the load of products

- Routing according to the barcodes and/or RFID chips of the products

Interfacing with Level 2 and all external equipment ensure operation of entire installation. The tests can be done with one product, and then with campaigns of several hundreads/thousands of products.

Our force in this type of process is to be able to design 3D environment in virtual way by perfectly positioning all the mechanical parts (conveyors or robots). We can also manage virtual stocks in order to validate the in and out stock logic before integrate the real stock. Being able to test processes upstream is a real competitive advantage.

Our speciality : transitic projects revamping

Supporting our client since severals years sometimes, we carry out new projects as well as revamping. We regularly start from a blank sheet of paper to which we apply a customer standard or an IESA standard, but it is certainly on revamping projects that we are most consulted! Thanks to our proven experience on several works, we became THE specialist of transitic revamping projects. Our experts know how to manage this type of project, either on the electrical part or in automation. Generally, the challenge is to put the plant back into production in a very short time. The critical issue is clearly the management of obsolescence and the optimization of restart time to minimize the impact on production.

We can also bring our know-how in missions of expertise and process optimization.

Key elements on logistic market

- Number of hours of work in 2022 : 1300H

- Number of people mobilized: 5

- Countries visited and Number of kilometers traveled: North America, Europe for 52 000 kms

- Revamping specialist, with more than 20 projects over the year

- Our Plug’n Test simulator allows us to optimize deadlines

- We integrate robot exchanges to validate stock I/O

- This sector requires a high rate of production: the use of Beckhoff and/or ADS equipment allows us to reach fast speeds of around 10 ms

What customers come for, according to our experts

Lâm, automation specialist

- We are a multi-brand integrator

- Our proven experience

- The adaptability and flexibility of our teams

- The possibility of testing processes upstream by virtually reproducing the environment (saving time and money)

- Our ability to move around the world

Harold, Simulation design office Manager

- The possibility of carrying out Virtual Commissioning, in particular on complicated projects at the level of “cadence” and “product follow-up”, exchange Niv1 and Niv2 (even up to Niv3)

- Our expertise in virtual reality and simulation

Michaël, Automation design office Manager

- Our global expertise in automation and electricity and the complementarity of our knowledge

- Our 15 years of know-how in automation

- Our ability to adapt to a large number of fields and to any technology

The last word with Guillaume, Projects Director

IESA is positioned as a major player in engineering in the logistics market. Its experienced teams put their know-how at the service of your needs. Your operators will be able to work in complete safety in your workshops. When you call on IESA, you can be sure of getting a solution. We are flexible and responsive to ensure that your planning requirements are met. Feel free to consult us for all your needs on new or revamping projects in the logistics market!