Technological Focus – IESA innovates to improve its customers’ HMIs

In order to provide our customers with a more complete and easier-to-read solution for their supervisory views, we have developed our interfaces by adding 3D elements.

In the world of industry, process supervision tools associated with Human Machine Interfaces (HMI) play an essential role in the monitoring, control and optimisation of industrial installations.

A few technical reminders

Monitoring: HMIs visually display real-time information on the status of industrial processes. This makes it easy to monitor variables such as temperature, pressure, flow or level.

Control: HMIs enable operators to control machines by adjusting parameters remotely. They can switch equipment on or off, adjust set values or make decisions based on data supplied in real time.

Alarms and Notifications: SCADA (Supervisory Control and Data Acquisition) systems can generate alerts and notifications when critical parameters exceed predefined thresholds.

Historical data: process monitoring tools typically record and store historical data on process performance. This data can be analysed at a later date to detect trends, patterns or recurring problems.

Reporting and analysis: HMIs can generate detailed reports on equipment performance, enabling industry managers to make informed decisions about preventive maintenance, operational efficiency and process optimisation.

Systems integration: SCADA systems are often connected to other systems such as PLCs (Programmable Logic Controllers), sensors, actuators, databases, etc. This enables more advanced automation and greater flexibility. This enables more advanced automation and centralised management of operations.

Industrial security: supervision tools and HMIs generally incorporate security measures to protect industrial systems against potential threats, such as unauthorised access, cyber attacks, etc.

In short, supervision tools improve the efficiency, safety and reliability of industrial operations while providing valuable data for strategic decision-making.

Our expertise at the service of our customers

At IESA, we are recognised for our high level of expertise in the field of industrial automation. We program PLCs, supervisory systems and HMIs, and update our customers’ programming standards. Drawing on our expertise in industrial simulation, we also create immersive tools for a wide range of purposes to support our customers, whether for technical validation, training or to make their interfaces easier to understand.

To make life easier for our customers, we wanted to make our supervision views more attractive and easier to read. Thanks to our virtual simulation specialists, we have created visual computer graphics that make them understandable at a glance! We have also designed a set of simple, evocative pictograms to make the interfaces intuitive to use.

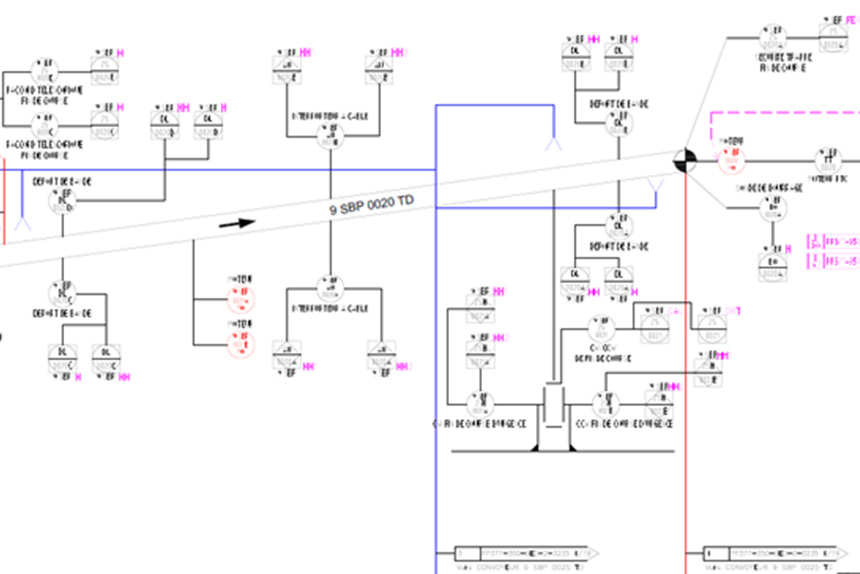

Before

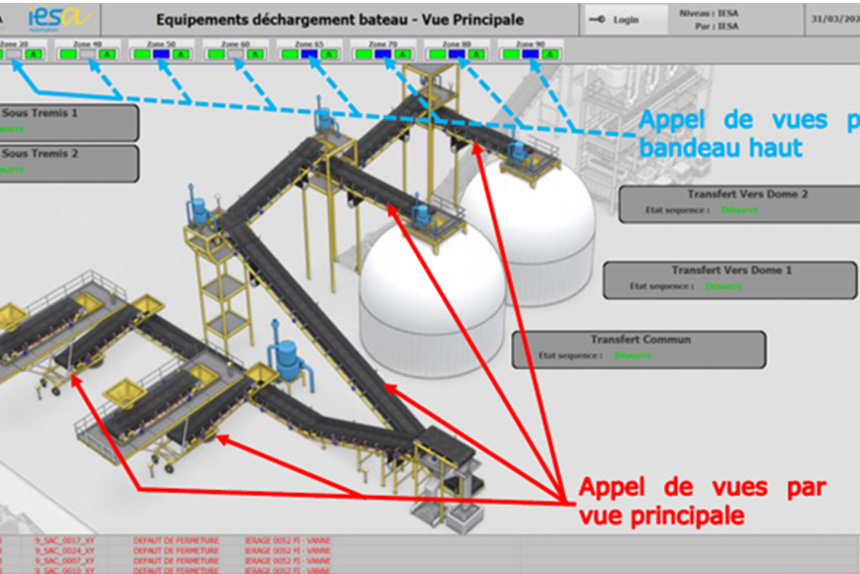

After

Using the mechanical drawings as a starting point, we reconstruct the 3D environment of the process, integrating all these functions and machines.

Initially created to meet the needs of a mountain resort operator, we then duplicated this process in a waste recovery plant, but this integration can be applied to any process. Here are a few examples of our work:

Télébus gondola lift at La Plagne and Teppes ski lifts at Les Ménuires

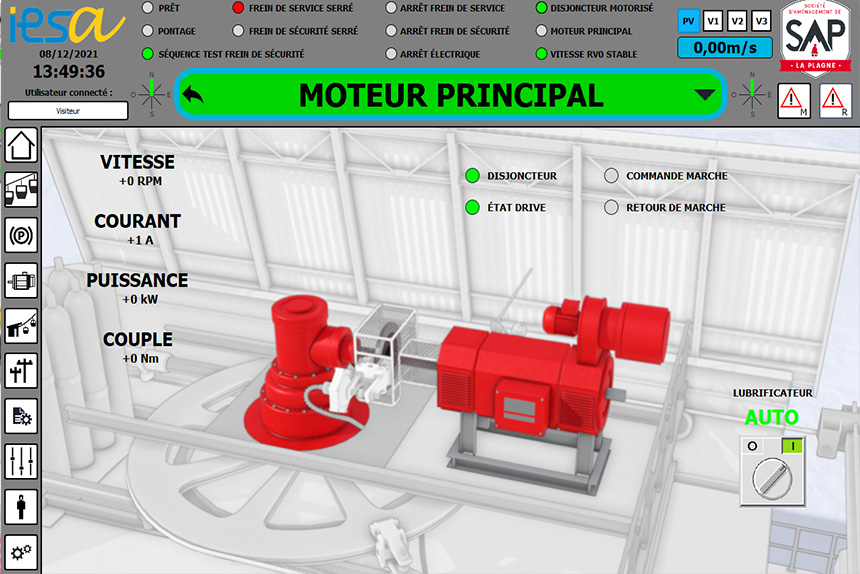

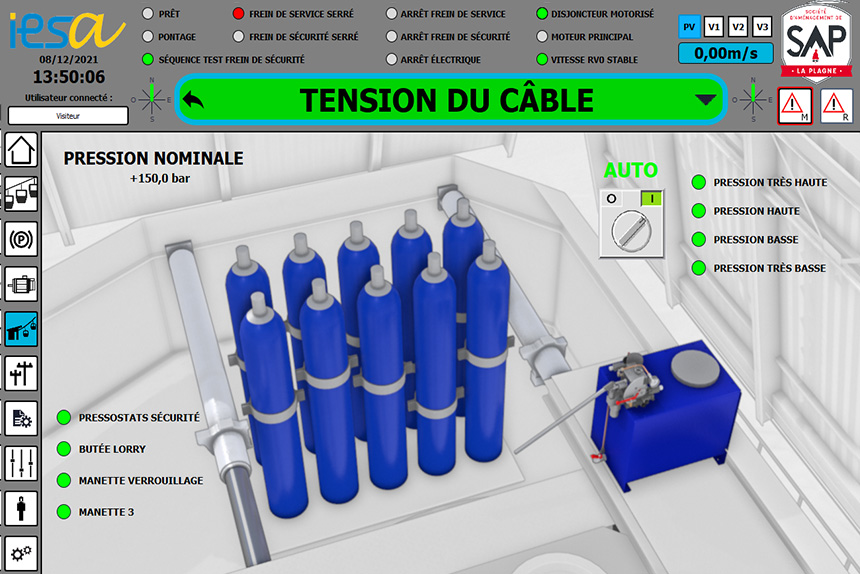

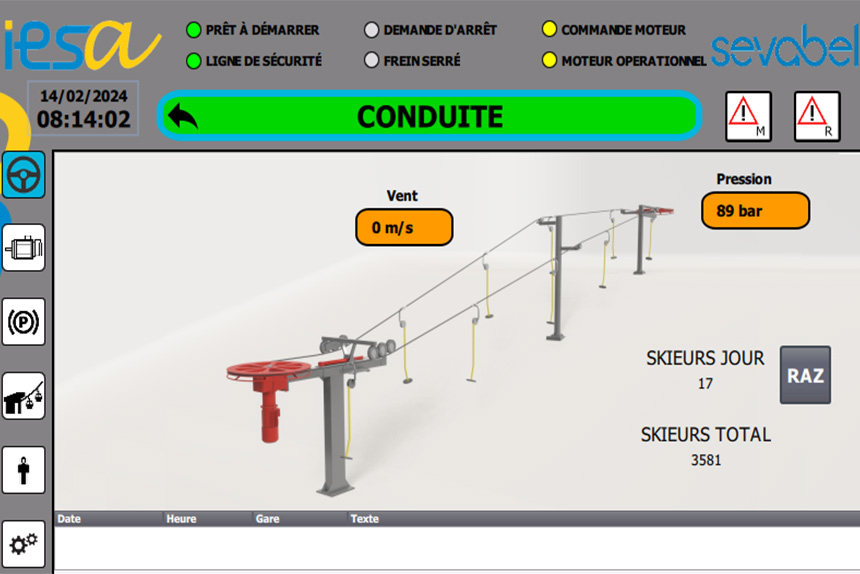

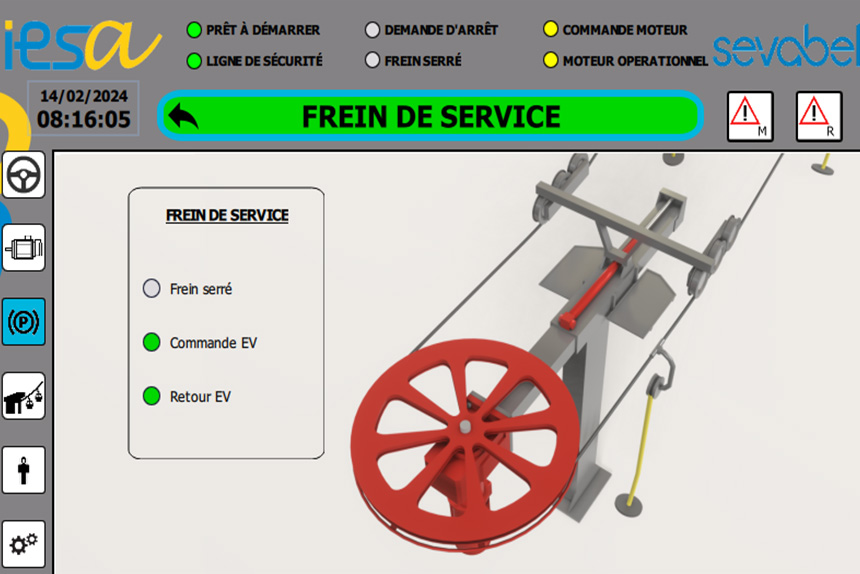

Driven by the desire to optimise the legibility of HMIs and thus improve the driving comfort of operators of ski lifts in the mountains, we were a driving force behind the creation of 3D views to enhance our interfaces, a solution that makes the information provided easier to understand.

We produced aesthetic computer graphics that were faithful to the real elements of the installation for various devices such as the TELEBUS cable car at La Plagne and the TEPPES detachable ski lift at Les Ménuires.

Our driving views were quickly adopted because they make it easier to read and control the installations on which they are integrated. It’s easy to get to grips with, and the driving experience is now ergonomic!

While we have considerably improved the quality of the visual rendering, we have also added technical value. For example, for each bypass, we have inserted a clear and exhaustive description of the faults involved. The same applies to annual tests, where the procedure to be followed and the test method used are given for each test code. We have also added a tool for filtering the fault log according to type. Finally, we have created a drop-down menu that allows you to access all the pages in the interface with a single click.

Motorisation

La Plagne

Cable tension

La Plagne

Conduite

Les Menuires

Frein de Service

Les Menuires

Bois Rouge Power station at La Réunion with Albioma

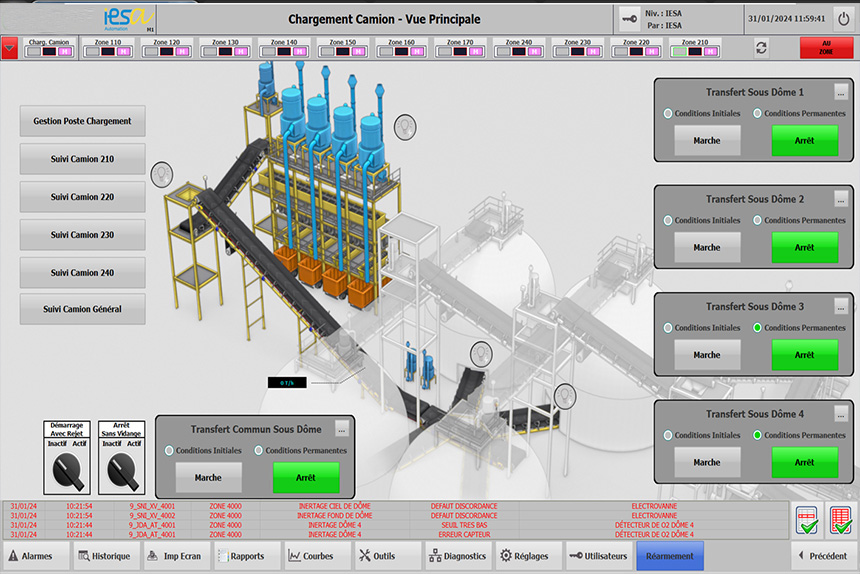

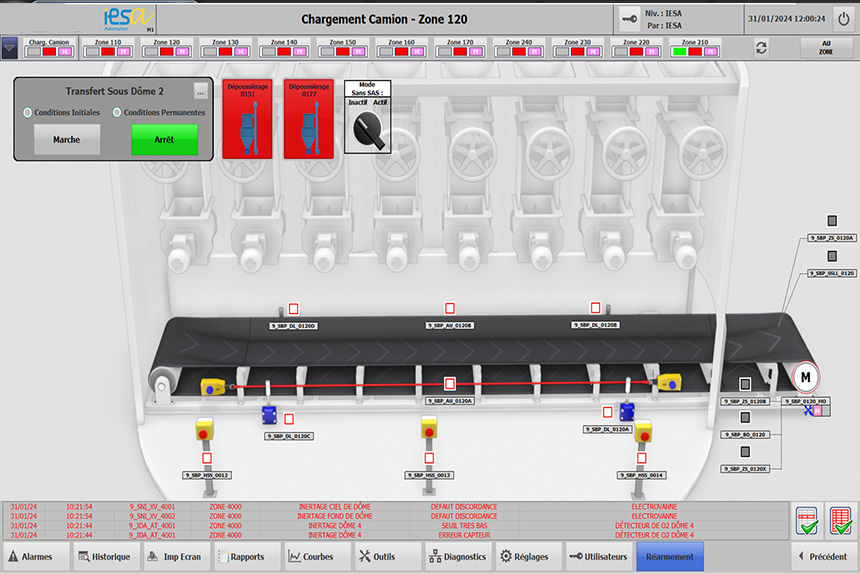

With our focus on innovation and continuous improvement, we wanted to improve the readability of our HMI views by emphasising the aesthetic aspect. We wanted to move away from the usual industry standards by making it easier for operators to get to grips with the installation. Using our simulation department, we recreated a virtual model of the entire plant based on the PID plans. This faithful reproduction of the real thing allows the process and all its functions to be visualised!

In this Power plant, we integrated the storage domes, the conveyors in the truck-loading area, the vibrating floors, the conveyors managing the unloading of the boats, the hoppers and their transfers, etc.

3D modelling also enables people with no technical knowledge to understand how the installation works.

What sets this solution apart is its infinite customisability. All the elements can be modelled as required. It also stands out for its legibility and immersive aspect. Operators can access supervision of the entire site from the control room via interactive 3D modelling.

Truck loading – Main view

Truck loading – Zone 120

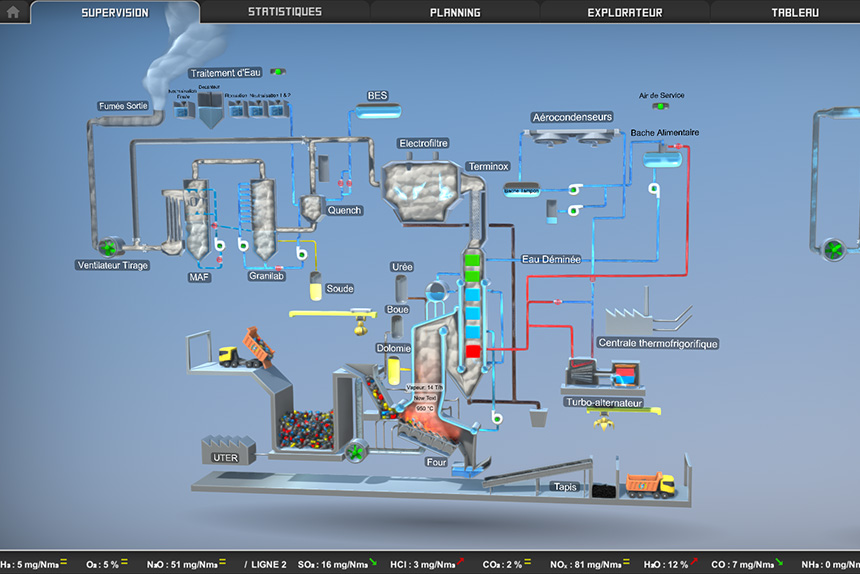

TEO, interactive supervision for the management of a waste-to-energy plant

A long-standing customer, this waste recovery plant has always been attracted by cutting-edge technologies.

Our automation and 3D simulation experts came up with a new interactive, voice-controlled supervision tool.

Our teams used existing synoptics to develop a more user-friendly tool incorporating 3D technology. The tool’s animation and interactivity make it easier to read.

Its 3D graphic display provides a clearer view of the plant’s operating status. It also provides access to a number of process indicators: levels, temperatures, fluids, etc.

Emission values and alarm monitoring are shown on a scrolling banner at the bottom of the screen, for greater transparency.

The files needed to organise the technical teams are available in a dedicated area.

The system can be operated either by voice command or by touching the screen.

This animated supervision tool is a real innovation in the world of industry. Its appeal is sure to attract other players in the environment sector. It will certainly be developed in other processes and other markets in the future.

Ecran principal – Supervision

Chargement du Camion – Supervision

A real competitive advantage, 3D makes it easier to read

The integration of 3D into our supervision views sets us apart from our competitors

- their user-friendliness and ease of reading, making for a fluid, simplified user experience

- by the customisation of environments and integrated objects: the views are therefore identical to the real process

- by connecting the views with other systems, such as the PLCs controlling the process.

Supervision interfaces have evolved to become more user-friendly, interactive and powerful, enabling users to better understand and manage industrial processes and installations. This evolution is set to continue as technologies continue to advance and user needs evolve. The IESA teams are ready to move in this direction.