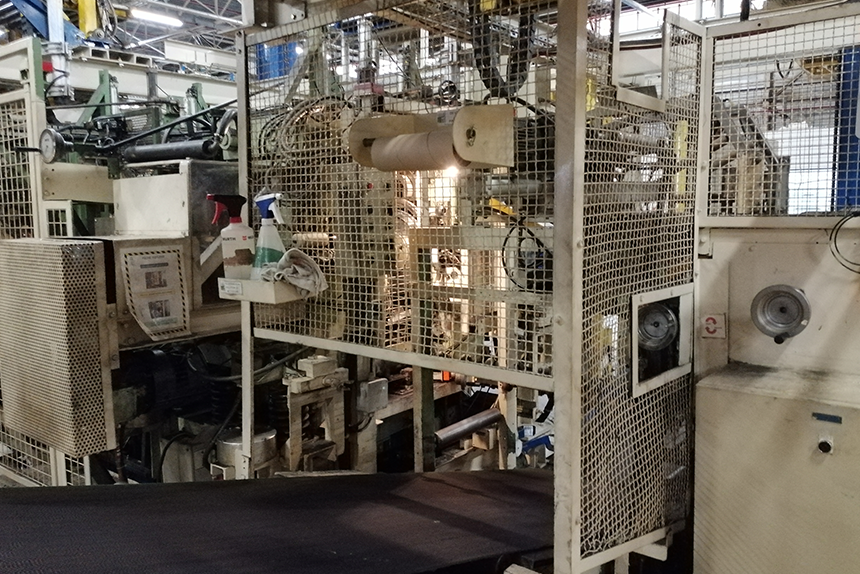

It was for a tire factory, in the after-curing workshop, that our automation engineers were involved with the Mono-CID products quality control machine (envelop tests).

The mission consisted of carrying out the revamping of the PLC controlling the machine without losing its qualification, migrating an Allen-Bradley PLC2 (1980) with 3 chassis (Rockwell) to a ControlLogix.

To achieve this, our team was to study the program, then convert the PLC program manually :

– 1 day for the change-over,

– 2 days of testing,

– 2 days of qualification,

The challenge was met, since the process was running again after only 5 days.

The Key Elements :

- More than 2,000 lines of code translated without any possibility of testing

- Communication with Level 2 to restart the process transparently

- Short mission length, accomplished in a single visit

#IESAAutomation #Automation #MonoCID #Revamping #AllenBradleyPLC2 #ControlLogix #Rockwell #Pneumatiques #Tyre #Tire