The context of this 3D simulator project for a tunnel boring machine

The teams at our specialized SIMPULSE Solutions entity have just successfully completed a major project for Bouygues Travaux Publics: the design, development, and delivery of a 3D simulator used to validate the automation of a tunnel boring machine well before it is put into service in the field.

Tunnel boring is a strategic process with high stakes: industrial simulation, and virtual commissioning in particular, support safe and efficient commissioning.

Customer objective: to secure and anticipate the commissioning of a tunnel boring machine

The challenges were clear:

- Reduce the risks associated with actual commissioning

- Validate the critical path of the erector process

- Work on automation and supervision in a virtual environment

- Gain flexibility and operational autonomy

Our scope of work: A tailor-made solution developed by SIMPULSE Solutions

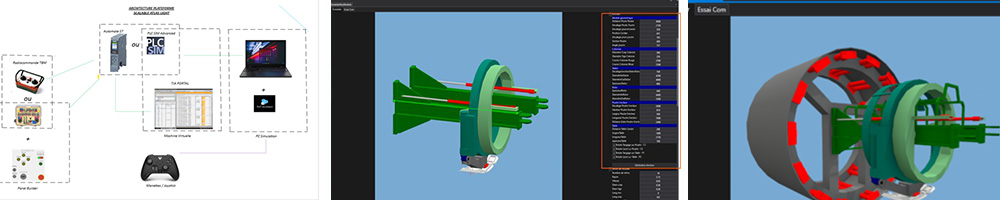

To meet this need, our industrial simulation experts designed a tailor-made Plug’n’Test® simulator, including:

- A 3D generation module for the erector based on mechanical data

- Supervision panel software interfaced via OPC UA

- Dedicated SIMETRIC® license

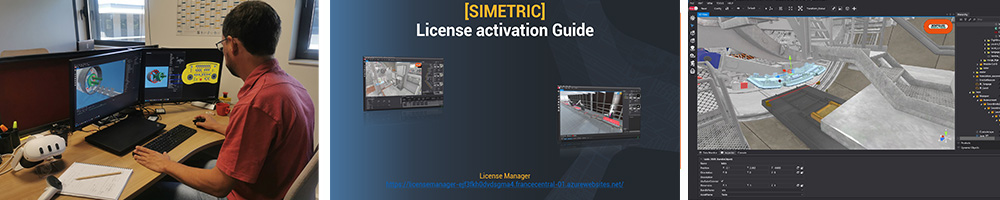

- On-site training at our premises, accompanied by technical support

Bouygues Travaux Publics is now autonomous on the tool, which will be deployed in the coming weeks on the target site.

A project led by the SIMPULSE Solutions teams

SIMPULSE Solutions, our entity dedicated to industrial simulation, works on cutting-edge issues in virtual commissioning, digital twins, and automation validation.

🔍 Want to know more? 📢 To discover the complete 3D simulator project developed for Bouygues Travaux Publics, visit the website of our dedicated entity 👉 SIMPULSE Solutions