Industrial automation: focus on an aluminum heat treatment plant in France

Industrial automation serving the aluminum industry

The aluminum sector is constantly evolving. From raw material processing to industrial applications, each stage of the production chain requires precision, reliability, and performance. One of the essential processes is aluminum heat treatment, which is crucial for improving mechanical properties and ensuring the quality of finished products.

In this context, industrial automation plays a key role: it enables equipment to be controlled with great precision, optimizes productivity, and ensures operational safety.

An industrial automation project in the aluminum market

IESA recently assigned an expert employee to a project in France, at the heart of an aluminum heat treatment plant.

Our mission?

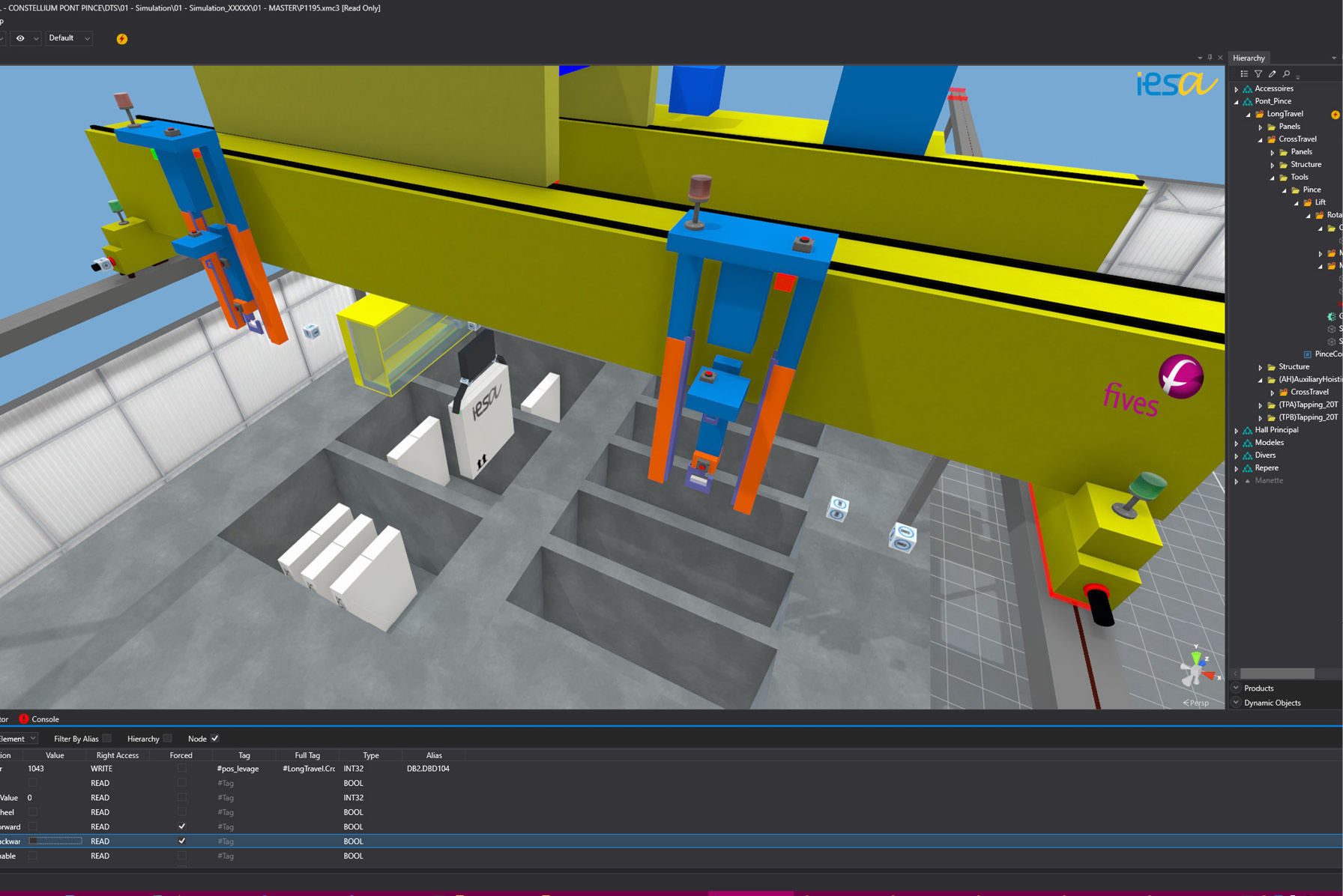

- Develop a dedicated PLC program to control a clamp bridge for handling aluminum trays.

- Support the customer during on-site commissioning, ensuring smooth, safe operation in accordance with process requirements.

This project is being carried out in collaboration with Fives Aluminium, a recognized player in industrial engineering.

Recognized expertise in industrial automation

Thanks to its expertise, IESA provides manufacturers with customized industrial automation solutions tailored to the constraints of each sector. Our services cover:

- The development and programming of PLCs,

- The integration of control and supervision systems,

- On-site commissioning,

- Technical support and maintenance.

Our work covers a wide range of high-stakes areas, such as aluminum heat treatment.

Industrial automation: field expertise for reliable processes

On this project, our expert Pierre was able to leverage his skills in industrial automation to ensure the success of the project in the aluminum sector. This commitment reflects our approach: working alongside our customers in the field to secure and optimize their processes.

IESA, your trusted partner for industrial automation projects

With this project in the aluminum industry, IESA has once again demonstrated its ability to support its customers in their industrial process automation projects.

Whether it’s industrial automation, industrial electricity, or industrial simulation, we put our expertise at the service of performance and innovation.

🔎 Do you have an industrial automation project? Contact our teams to find out more!