3D Simulators

Virtual Reality, Augmented Reality, … and Industrial Reality !!

Starting in 2006, IESA decided to integrate “new” digital technologies, persuaded of their considerable potential in industry.

Today, with skills acquired in virtual reality, augmented reality, digital simulation and modeling, we are proud of the numerous successful projects we have completed in this domain. Our know-how in project mode, our knowledge of the world of industry, and our careful listening to our clients’ needs allow us to respond to their expectations, within their budgets.

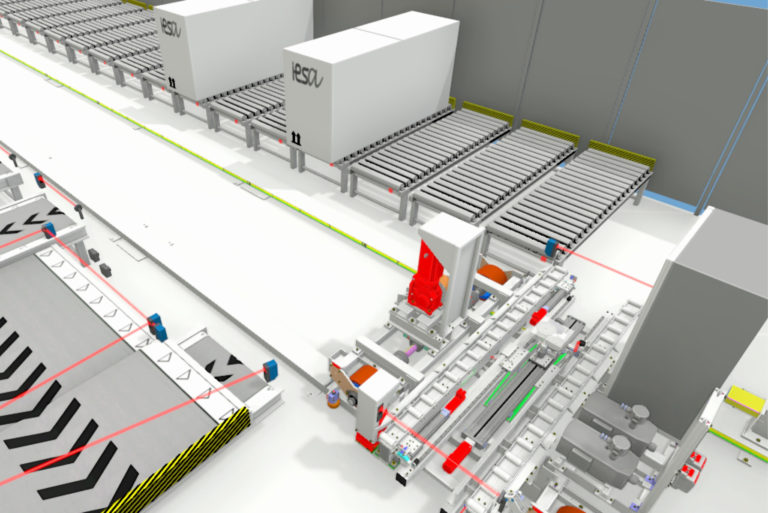

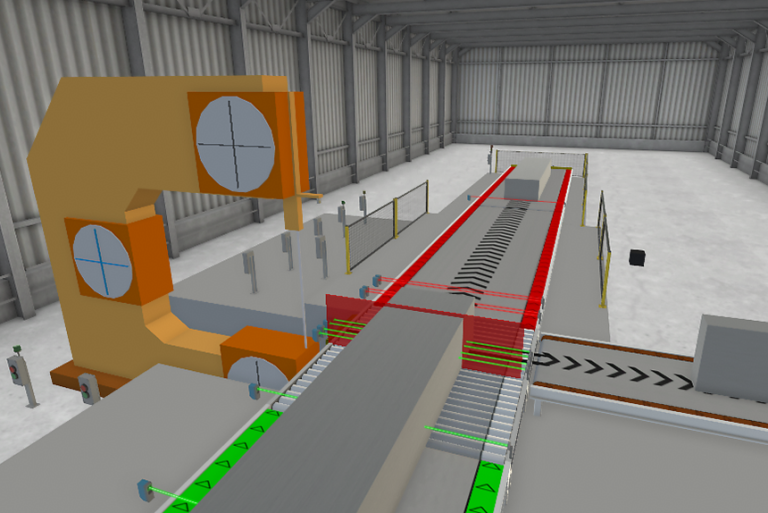

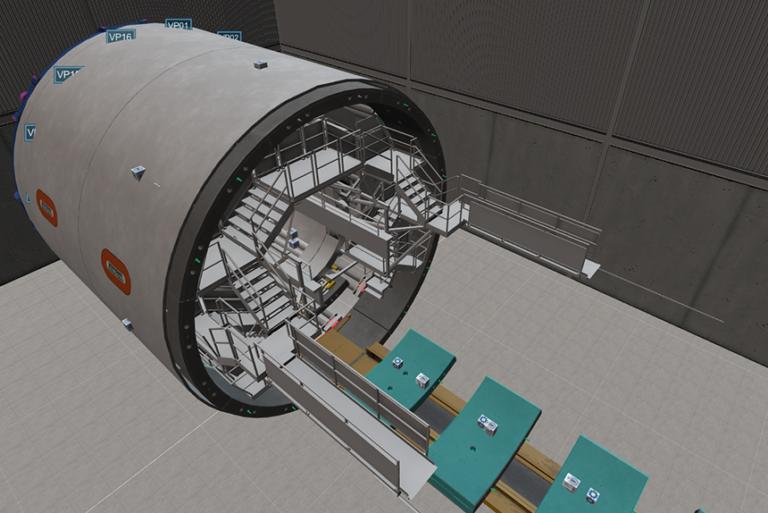

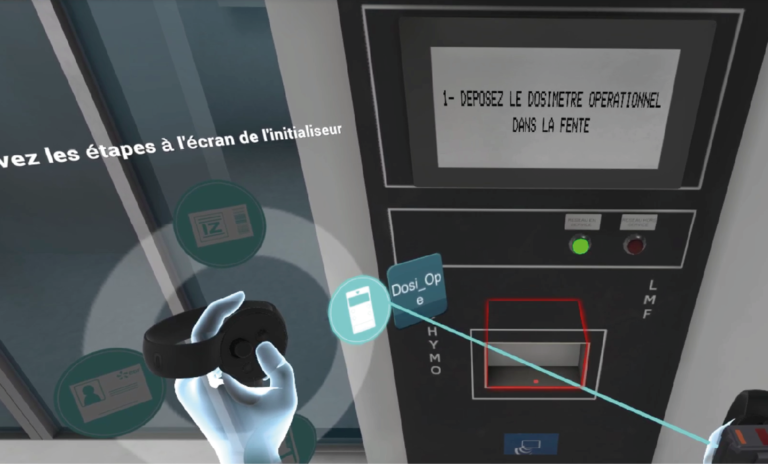

It’s by working systematically from real-world on-the-job needs that we have built immersive tools used with varying goals : sales tools, decision-making tools, technical validation, automated process validation, industrial training (operational, maintenance, safety, … ), technological showcase. Because the real issue for our clients is to increase their competitivity in their own domains of expertise, IESA develops adapted customized virtual solutions.

OUR EXPERTISE

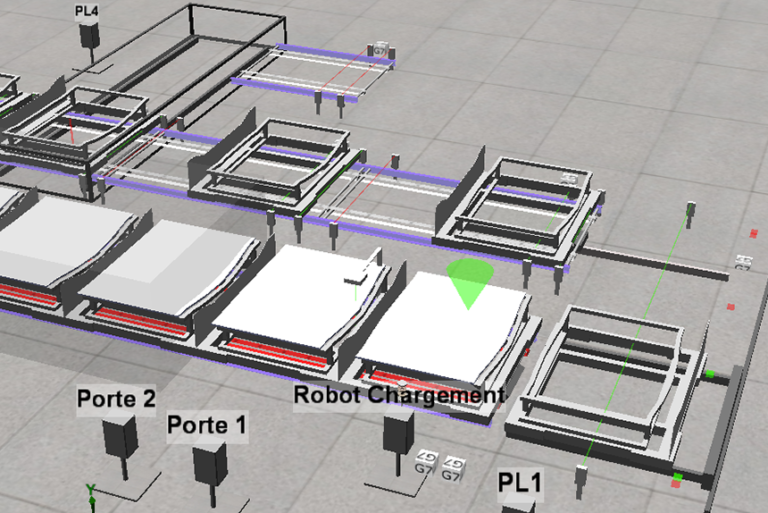

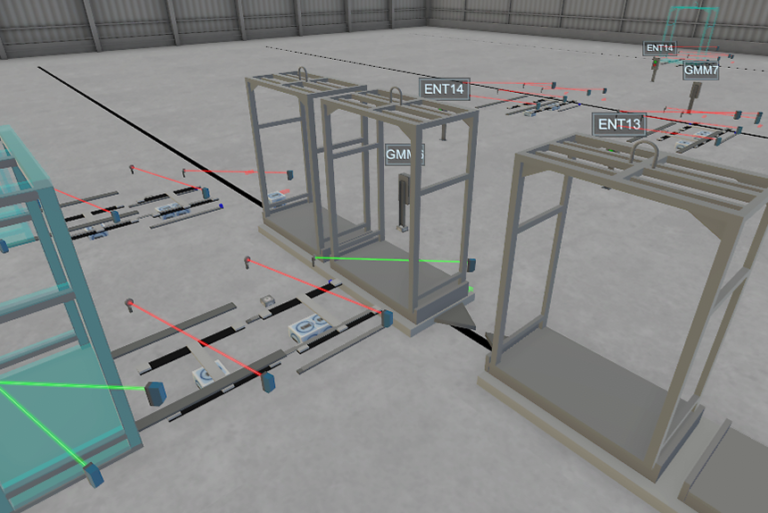

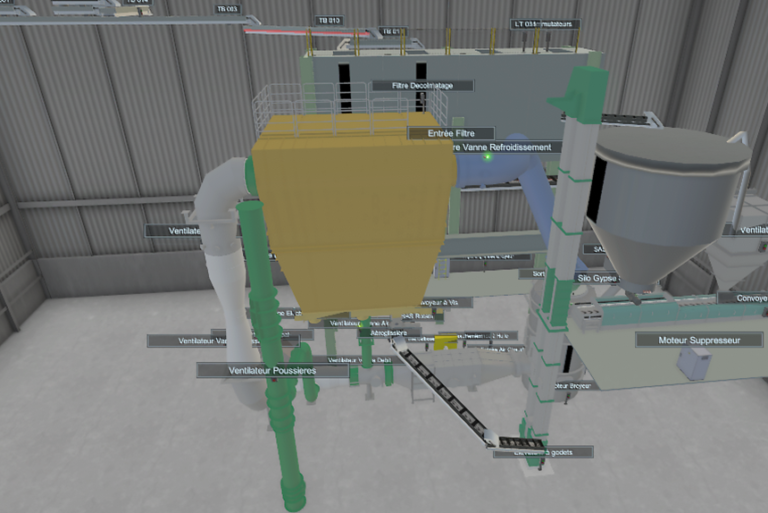

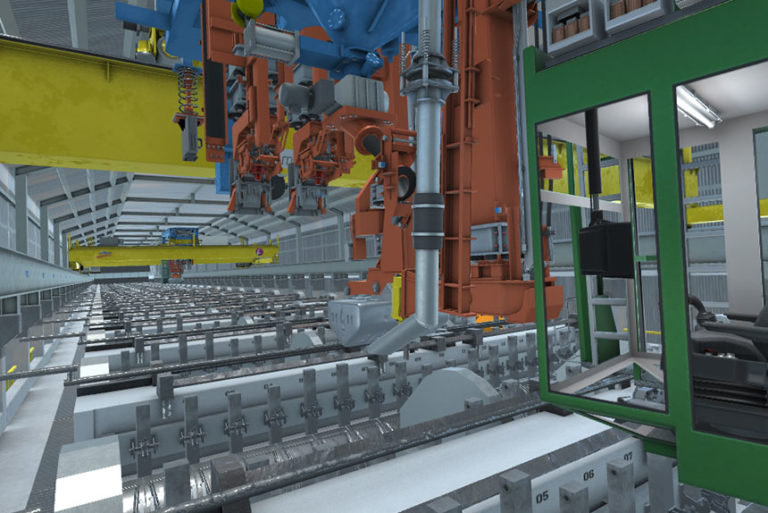

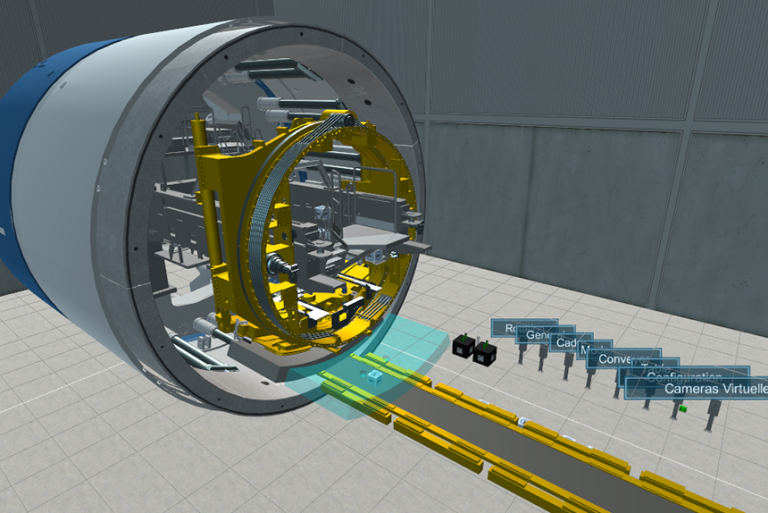

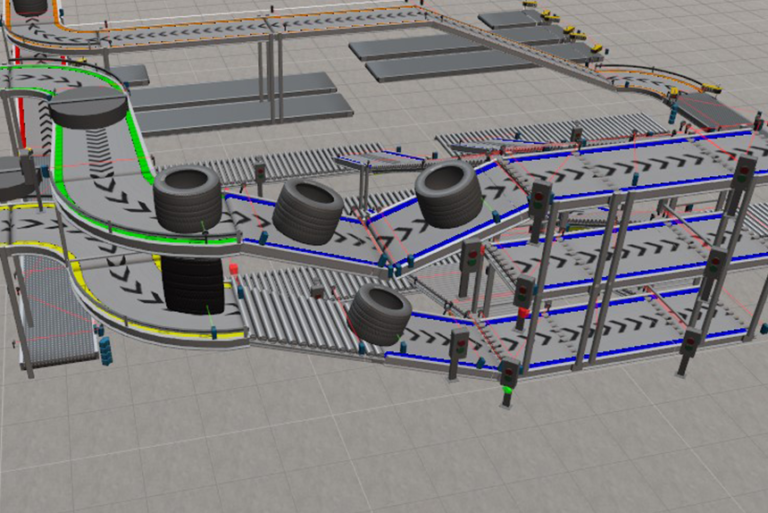

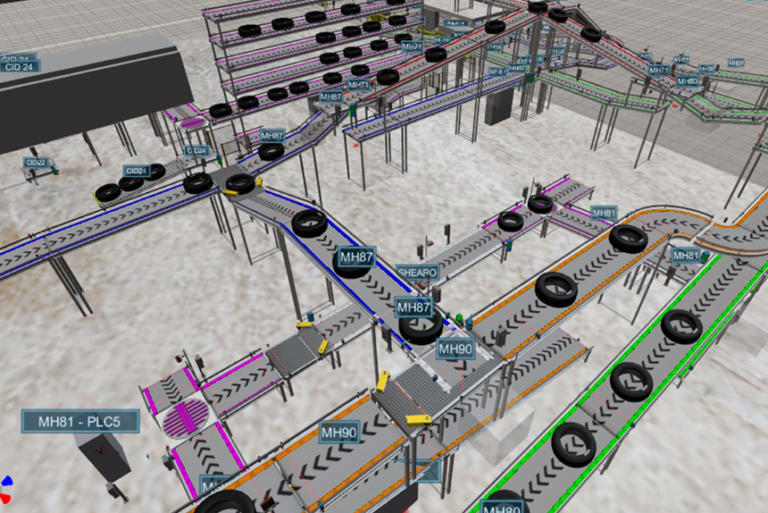

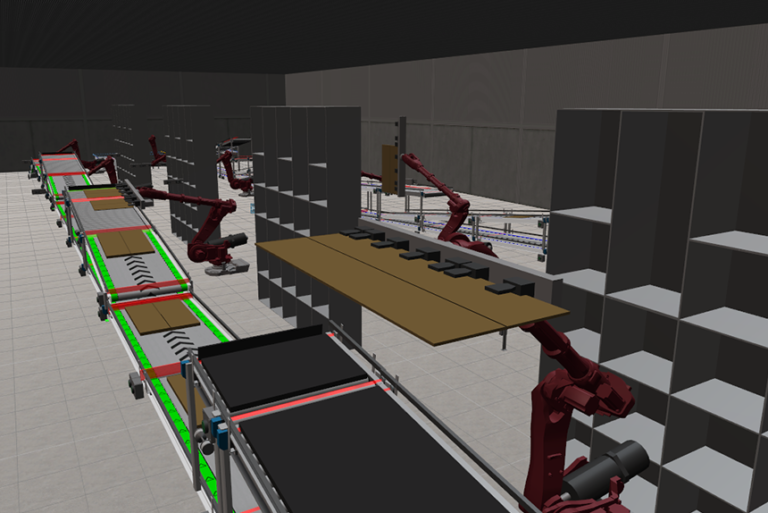

3D Simulators

- Virtual reality

- Augmented Reality

- 3D

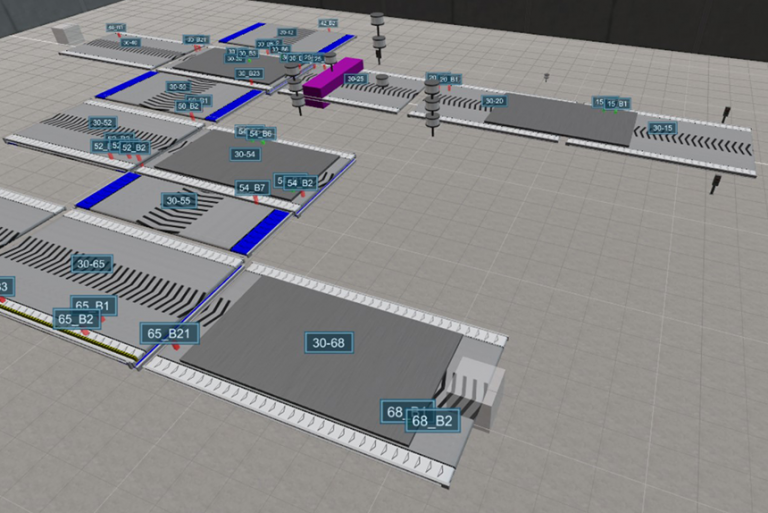

- Digital twinning

- Serious game

- Digital mock-up

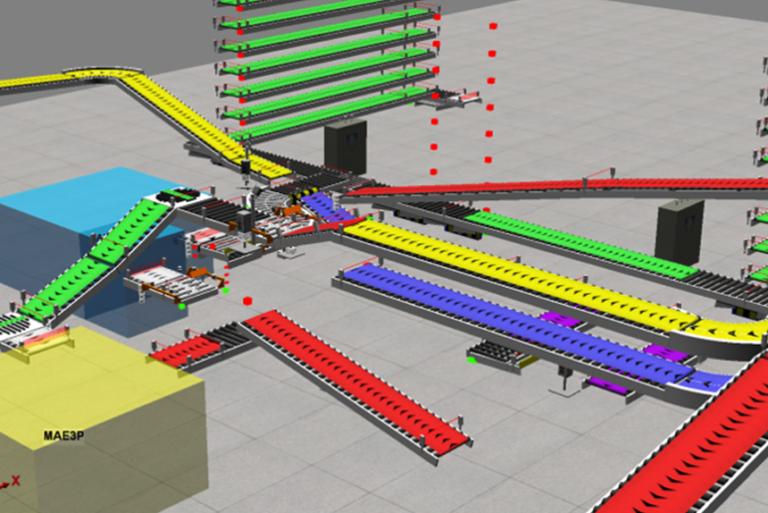

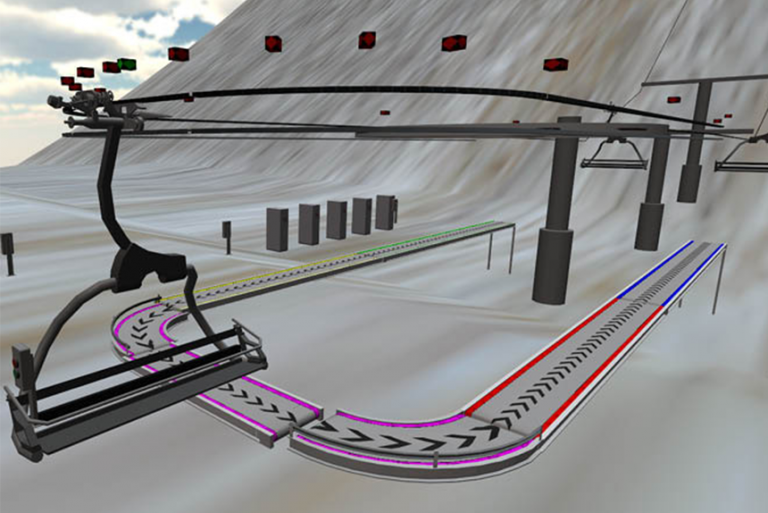

- Simulation of automated systems (Plug'n Test®)

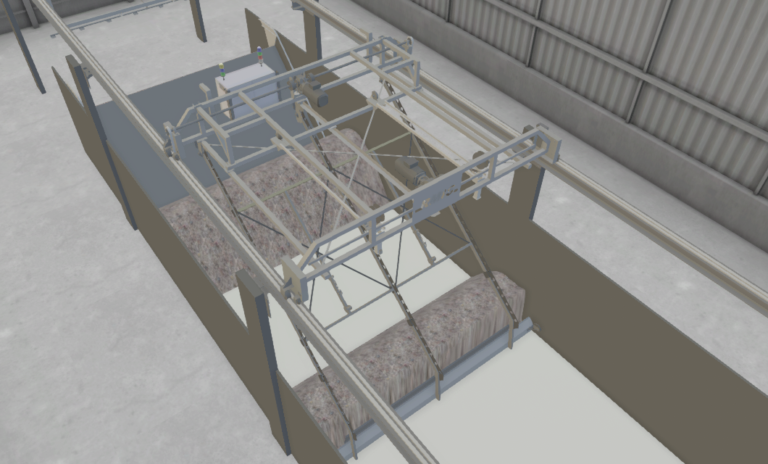

- Simulation of installation operations

- Training simulators

- Design and sales assistance simulators

OUR PARTNERS